The role of irrigation lines in dental implantology

Understand the differences between manual, mechanical, single and double irrigation lines

In implantology and oral surgery, the term “irrigation line” refers to the system used to deliver irrigation fluid during dental implant surgery. The irrigation line plays a crucial role in maintaining a clean and sterile surgical field and in cooling the area during surgery. Indeed, when creating an implant site, managing temperature is essential to ensure that the implant is osseointegrated correctly. One of the main causes of necrosis is in fact overheating of the bone. Friction created by dental burs can cause temperatures to soar and inflict considerable damage. A temperature of over 47° C for more than one minute causes a risk of thermal necrosis of the bone tissue.

To avoid overheating the bone, the surgical bur must be properly cooled with an adequate but not excessive flow of liquid. This liquid flow can be ensured through an irrigation system.

In addition to preventing overheating and thus avoiding potential damage to the bone, irrigation lines make it possible to:

- Clean: irrigation fluid helps wash away bone debris and other particles generated during the drilling process. This keeps the surgical area clear and provides better visibility for the surgeon.

- Maintain sterility: the irrigation fluid used is sterile and helps maintain a sterile surgical environment and minimise the risk of infection and contamination during the procedure.

- Reduce friction: in addition to cooling and cleaning, the irrigation fluid can help reduce the friction of burs and instruments used in implant surgery, ensuring smooth and precise drilling.

The infusion set is a crucial component of implant surgery, as it helps ensure the success and safety of the procedure by maintaining a clean and sterile surgical environment, preventing overheating and facilitating the surgical process.

Mechanical and manual irrigation lines

Irrigation systems can be of two types: manual or mechanical, different for each physiodispenser (commonly called micromotors, surgical motors or implant motors).

Manual irrigation systems are reliant on the action of the assistant. They are equipped with a button-based flow regulator that allows the assistant to manage the jet and keep the surgical field clean and the implant site cool. The system is also suitable for irrigation during the final fixation of implants. Manual irrigation is a simple and economical method. It does not require complex machinery or automation, but is subject to the experience and skill of the assistant.

The advantages of manual irrigation are:

- Control: Manual irrigation involves the assistant manually administering the irrigation solution to the surgical area with direct control over the flow rate and the precise location of irrigation.

- Flexibility: Manual irrigation allows flexibility in adjusting the irrigation flow as needed during the procedure. The operator can easily pause or increase the flow when needed.

The mechanical irrigation systems are different for each physiodispenser and, as already mentioned, are designed to allow the implant micromotor to better manage the cooling jet, keeping the bur and the implant site at the optimum temperature.

The main advantages are:

- Continuity: mechanical irrigation systems are designed to provide a constant and controlled supply of irrigation solution throughout the procedure. They can maintain a continuous and constant flow rate, which can be important for precise and complex surgery procedures.

- Repeatability and standardisation: mechanical irrigation systems not only reduce the assistant’s fatigue but also ensure that irrigation of the implant site is always the same under all conditions.

Both types of irrigation lines are sterile disposable devices stored in medical blister packs, equipped with double adhesive labels for convenient traceability management.

The choice between manual and mechanical irrigation in implantology depends on various factors, including the surgeon’s preference and the complexity of the procedure. Simple implant procedures can be adequately managed with manual irrigation, while complex cases that require precision can benefit from the consistency and automation provided by mechanical irrigation systems.

Mechanical irrigation lines: differences between single and double irrigation

There are two main types of mechanical infusion sets: single irrigation and double irrigation. These irrigation systems are used to deliver fluids, usually sterile saline solutions, to the surgical area during the implant procedure. In the double irrigation or double mechanical irrigation lines, there is a Y-connector that allows the flow of saline solution to be split and allows internal and external irrigation if required, thus transforming single irrigation into double irrigation. Double irrigation is used in some contrangles which, in addition to the internal method, have a hollow head to irrigate the outside.

Here are the main differences between single and double irrigation systems:

1. Monoirrigation: uses a single irrigation line that delivers the irrigating solution to the surgical area. The single irrigation line is generally connected to the implant motor, which then delivers fluid to the drill or surgical instrument.

2. Double irrigation: the use of double mechanical irrigation lines allows two separate irrigation lines to be used. External irrigation ensures direct cooling of the bone surface, internal irrigation prevents overheating of the surgical bur due to friction. Double irrigation systems offer better control and optimisation of fluid delivery. Surgeons can adjust the flow rates of each line independently to meet the specific needs of the procedure.

In summary, the choice between single and double irrigation systems in implant surgery depends on the complexity of the procedure and the surgeon’s preference. However, several studies recommend a combined system of both internal and external irrigation to maximise the irrigation effect. These include the study by Gehrke et al. (2015), which showed that the system with both external and internal irrigation is more successful in reducing internal thermal heat in more conventional drilling sequences, even if the drill length is longer.

The components of mechanical irrigation lines

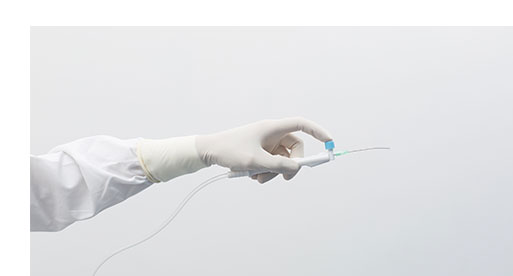

The different mechanical irrigation lines on the market differ from one another regarding the peristaltic pump section, i.e. the end that has to connect to the micromotor. However, the following components can be identified in each mechanical irrigation line:

- The perforator, which helps to perforate the saline bag port and is equipped with an air filter with an “Open and Close” system to manage the flow of the liquid.

- The Roller, which allows the flow to be adjusted or stopped all together in one easy move, so you can manage the flow rate of the liquid to meet your needs.

- The silicone tip, which helps to connect the irrigation line with the cooling needles in the various handpieces available on the market.

- Present in certain models, the connecting tap optimises the simultaneous connection of various pipes, preventing liquid and pressure loss.

- The medical-grade, elastic and flexible PVC tube, which optimises the connection and cooling flow from the bag to the handpiece.

- The section for the peristaltic pump, i.e. the cross-section of the hose for the peristaltic pump which is made of soft silicone, and which varies depending on the motors on which the fusion set will be mounted.

- The S-shaped pipe clamp to arrange connecting pipes and fix them in place. These elements allow the irrigation line to be attached to the feed tube of the handpiece

- The Y-connector to divide the flow in two and enable internal and external irrigation where necessary. The connector can be used for external and internal irrigation, turning single irrigation into double irrigation.

The choice between different irrigation lines in implantology depends on various factors, including the surgeon’s preferences, the complexity of the procedure and the equipment available. Simple implant procedures can be adequately managed with manual irrigation, while complex cases requiring precision can benefit from the flow constancy and automation provided by single or double mechanical irrigation systems.

Ultimately, it is important for professionals in the dental field to select the irrigation method that best suits their specific needs and ensures the safety and success of the implant procedure.

Sources

Gehrke, S.A., Bettach, R., Taschieri, S., Boukhris, G., Corbella, S. & Del Fabbro, M. (2015) Temperature changes in cortical bone after implant site preparation using a single bur versus multiple drilling steps: an in vitro investigation. Clinical Implant Dentistry and Related Research 17: 700–707. https://onlinelibrary.wiley.com/doi/10.1111/cid.12172

Alevizakos V, Mitov G, von See C. Guided Implant Placement Using an Internally Cooling Surgical Template: A Technical Note. J Oral Implantol. 2020 Oct 1;46(5):533-535. doi: 10.1563/aaid-joi-D-19-00312. PMID: 32315423. https://pubmed.ncbi.nlm.nih.gov/32315423/

Lavelle C, Wedgwood D. Effect of internal irrigation on frictional heat generated from bone drilling. J Oral Surg. 1980 Jul;38(7):499-503. PMID: 6929901. https://pubmed.ncbi.nlm.nih.gov/6929901/

Timon, Charles & Keady, Conor. (2019). Thermal Osteonecrosis Caused by Bone Drilling in Orthopedic Surgery: A Literature Review. Cureus. 11. 10.7759/cureus.5226. https://www.researchgate.net/publication/334664460_Thermal_Osteonecrosis_Caused_by_Bone_Drilling_in_Orthopedic_Surgery_A_Literature_Review